Interior coatings

DIN EN 13300 assigns interior coatings to different classes based on end use, chemical type of binder, gloss*, largest grain size, wet scrub resistance* and opacity*.Wet scrub resistance* and opacity* are particularly important in defining the quality of an interior coating.

Wet scrub resistance*

Wet scrub resistance describes how well a coating can be scrubbed with a damp cloth. RMI tests wet scrub resistance in accordance with DIN EN ISO 11998 and classifies according to DIN EN ISO 13300.

A coated PVC film strip being tested on a wet scrub tester

Allocation of wet scrub resistance classes in accordance with DIN EN 13300

Hiding power (opacity)*

Opacity describes how well a surface is being covered. In practical terms, this means that you need to apply a paint with a very hiding power only once, whereas a paint with less good hiding power may need two or three coatings to achieve a good (well-covered) result.

The specified spreading rate is also important. It expresses what volume of material is required to achieve the class indicated.

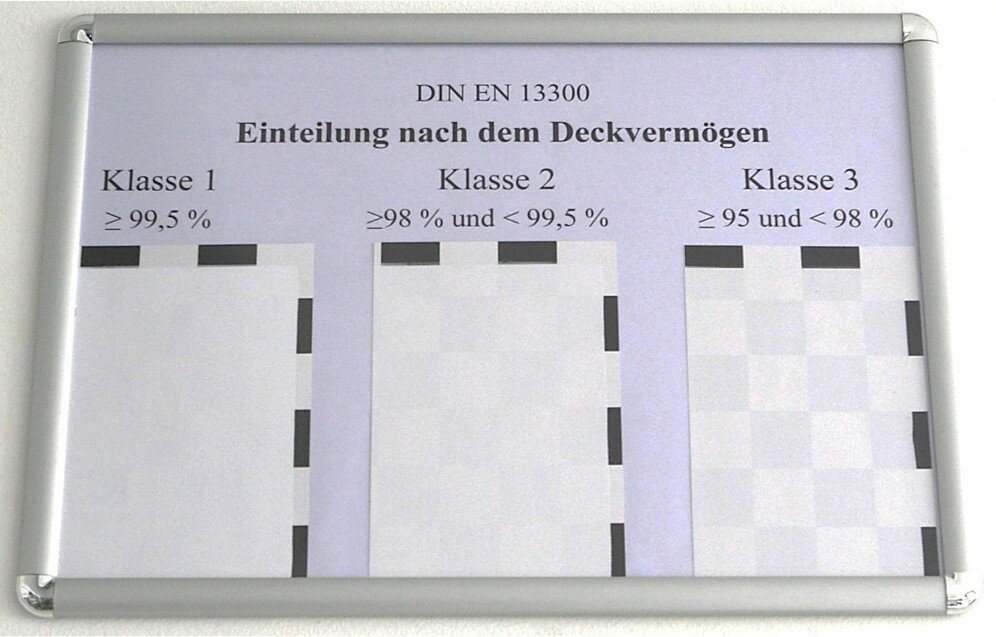

The figure ‘hiding power charts class 1 – 3’ depicts examples of different hiding power classes. Class 1 is the best class, where the covered checkerboard substrate is no longer recognisable. In class 2 it is still slightly visible and in class 3 it is clearly visible. Class 4 is not shown.

The hiding power is specified as the ratio of lightness on the black surfaces relative to the lightness on the white surface given in units of percentage. To precisely calculate the hiding power at the specified spreading rate, a linear interpolation of the values of two cards is used. The hiding power at the specified spreading rate is assigned to a specific class in accordance with DIN EN 13300.

* Accredited test